Downstream Chemicals

OVERVIEW

Xspiceo’s Downstream Chemicals safeguard crude- and condensate-distillation, catalytic cracking, reforming, hydrotreating, tank-farm and product-blending units. From high-activity antifoulants that keep pre-heat trains clean to low-ash antifoams for vacuum columns and cetane-boosters for diesel, every formulation ships with ISO-backed QA, rapid logistics, and refinery-side technologists who convert chemical spend into margin per barrel.

Nothing erodes refinery profitability faster than heat-exchanger fouling, column flooding, off-spec fuels or unplanned shutdowns. Xspiceo Global Traders merges 36 years of water- and process-treatment science with refinery operations know-how to create a single-source portfolio of Downstream Chemicals that:

-

Extend run lengths between turn-arounds

-

Reduce fired-heater fuel by controlling ΔT and ΔP

-

Protect metallurgy in acidic, amine-rich and chloride-laden zones

-

Deliver on-spec gasoline, diesel and jet fuel—first pass

PRODUCT LINEUP

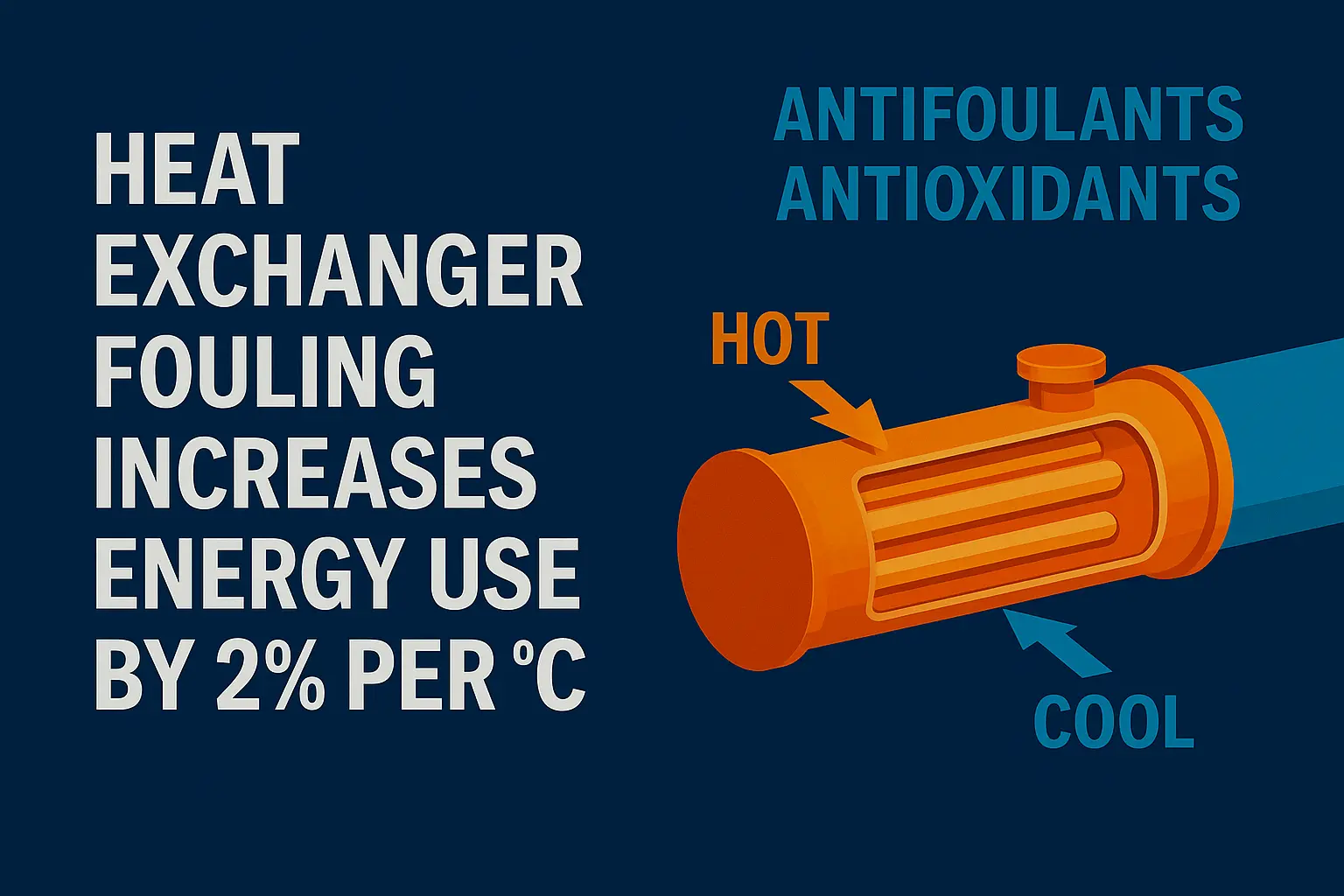

Process Antifoulants & Antioxidants

Coke precursors form when unsaturated species polymerise under heat soak. X-Guard™ AF100 donates hydrogen to free radicals, reducing fouling rate by up to 0.03 °C/day—verified in a 250 kbpd crude unit. For sulphidic environments, a PBTC-60 % co-blend disperses iron sulphide fines, sustaining < 1 bar ΔP across pre-heat exchangers for an entire 18-month run.

Our Products:

X-Guard™ AF100, HEDP-60 %

Desalting & Emulsion-Break Packages

High-TAN and tight W/O emulsions drag salt and water into crude heaters, causing tube ruptures. Saltex™ DS300 employs a dual charge-balanced surfactant system that collapses emulsions within 45 seconds, boosting desalter efficiency from 89 % → 96 % and cutting furnace tube scaling by 55 % against baseline.

Our Products:

Saltex™ DS300 (quaternary emulsion breaker)

DOSS-40 %

Neutralising & Filming Corrosion Inhibitors

Chloride-rich overhead systems experience flash-corrosion and ammonium chloride salts. Xspiceo’s zinc-tolyltriazole blend forms an adherent film on copper alloys, while SDMDC-40 % scavenges O₂ in condensate. A neutralising-amine package balances pH 6.8 – 7.2, eliminating top-plate leaks in a 70 kbpd VDU within 10 days.

Our Products:

Tolyltriazole + Zn synergy

SDMDC-40 %

PBTC-50 %

Column, Vacuum & Coker Antifoams

Traditional polysiloxane antifoams contaminate downstream catalysts. Foam-Zero™ C172 is siloxane-free, sustaining 60 % foam knock-down in VHGO vacuum towers without catalyst fouling. In delayed cokers, a slug dose of 20 ppm prevents sudden foam-over events and reduces wet-dump frequency by 25 %.

Our Products:

Foam-Zero™ C172 (siloxane-free)

CAPB

Cooling- & Boiler-Water Treatment

Refinery cooling towers face cyclic chlorides, organics and bio-load. Xspiceo’s BKC-50 % quaternary plus CMIT/MIT-14 % isothiazolinone maintain planktonic counts < 103 CFU/mL. HEDP-60 % prevents CaPO₄ scaling up to LSI +3, while PBTC-50 % provides mild-steel protection in 52 °C recirculating water. Our Products:

BKC-50 %

CMIT/MIT-14 %

HEDP-scale blends

Why partner with Xspiceo for midstream flow assurance?

For more than three and a half decades Xspiceo Global Traders has stood at the confluence of water-treatment consultancy and industrial chemical trading. Our organizations main USP’s are:

-

Vendor-neutral chemistry — we integrate seamlessly with any pigging, heating or DRA hardware.

-

Rapid logistics — dual warehouses near Chennai Port deliver within 72 hours across South Asia & GCC.

-

Data-driven dosing — cloud dashboards align residuals with flow KPIs; no guesswork.

-

ESG alignment — solvent-lean, low-tox packages help you hit emission and discharge targets.

Need a custom blend or technical data sheet? Contact Us